COMPONENT DESIGN FOR ASSEMBLY

After the final concept presentation, MWDesign will focus on the approved product concept. This will be done primarily through 3D CAD modelling. We will further development the CAD models into precise components incorporating all features from the final concept design. The objective is to develop the design to allow us to create a prototype for testing, before investing in tooling.

Focusing on individual part components, MWDesign will refine the components and design out the cost to enable us to maintain quality while meeting our budget cost. We will begin engineering the parts for the product, focusing on functional aspects of the design.

COMPONENT DESIGN FOR ASSEMBLY

After the final concept presentation, MWDesign will focus on the approved product concept. This will be done primarily through 3D CAD modelling. We will further development the CAD models into precise components incorporating all features from the final concept design. The objective is to develop the design to allow us to create a prototype for testing, before investing in tooling.

Focusing on individual part components, MWDesign will refine the components and design out the cost to enable us to maintain quality while meeting our budget cost. We will begin engineering the parts for the product, focusing on functional aspects of the design.

COMPONENT DESIGN FOR ASSEMBLY

After the final concept presentation, MWDesign will focus on the approved product concept. This will be done primarily through 3D CAD modelling. We will further development the CAD models into precise components incorporating all features from the final concept design. The objective is to develop the design to allow us to create a prototype for testing, before investing in tooling.

Focusing on individual part components, MWDesign will refine the components and design out the cost to enable us to maintain quality while meeting our budget cost. We will begin engineering the parts for the product, focusing on functional aspects of the design.

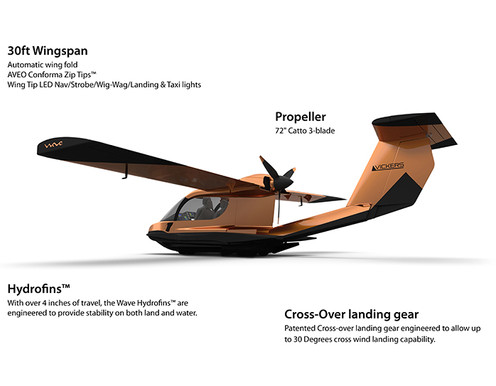

VICKERS WAVE

A light, safe and sexy amphibious sport aircraft.

The task was to create animated renders of the the Wave from CAD data showing the features to potential investors and customers.

When a man’s passion spills over to his work you know something special is about to happen. Paul Vickers decided to give up the day job to design and build the most beautiful amphibious light aircraft ever dreamed of.

Paul's aim from the beginning was to design a cost effective aircraft that felt at home on both land and sea. MWDesign had the privilege of bringing his design alive with a series of renders.

The Wave by Vickers Aircraft Company is packed with enough horse power and special features to make Howard Hughes jealous.

The wave can fly using Avgas or regular petrol, cruse at 222kmph for 1333km or from Herne Bay to Nelson and back. The Wave was designed to fit on a trailer and only require 185 metres of clear water or grass for take off and landings, your weekends will never be the same again.